3. VCT & SVT

TYPES OF RESILIENT FLOORING MATERIALS

- Vinyl floor

- Sheet Vinyl

- Luxury vinyl tiles

- Rubber

- Polymeric

- Linoleum

- PVC floor

- Floor

- Cork floor

- Anti-slip floor

- Acoustic floor

- Sports floor

- Natural flooring

- Vinyl tile

- Vinyl composition tile

- Tile

- Wall base

- Moldings

- Stair treads

1. STATIC LOADS - DENTING TESTING

Static Load Limit Testing of Resilient Flooring Products

Some resilient flooring manufacturers are claiming extremely high (PSI) static load limit ratings for their flooring products. This has led to confusion in the market place where architects, specifiers, designers and end users are led to believe that they are better protected against indentation and damage to the flooring products they have chosen than they are in reality. The purpose of this document is to explain static load limit testing and ensure that the end users, expectations of indentation resistance and recovery from indentation are realistic.

Static load testing, as it relates to resilient flooring generally refers to ASTM Test Method F-970, titled Standard Test Method for Static Load Limit. This test method is designed to evaluate the ability of a flooring product to withstand or recover from indentation. In the test method, a load for example, 175 pounds per square inch (PSI), is applied to the flooring for 24 hours. The load is then removed, and the material is allowed to recover f or another 2 4 hours after which the amount of residual indentation is measured. The pass/fail criterion is a residual indentation of no greater than 5 mils.

Following are important considerations you should know regarding static load limit testing:

1) Static load testing is currently performed on an uninstalled product. The same test conditions utilized on an installed product can give very different results, generally worse and sometimes much worse.

2) 2) ASTM product specifications, which largely govern the consensus specifications to which most U.S. resilient flooring manufacturers claim to conform, do not cite a static load requirement higher than 250 PSI for any product specification covering the category of resilient flooring.

3) Few objects within a residential household exceed a 125 PSI loading on the surface of a floor and commercially few objects exceed 750 PSI.

4) Since static load testing is generally performed for longer time periods (24 hours or more), other test methods have been developed to measure short-term indentation resistance. These tests are utilized to evaluate a product's hardness or ability to resist indentation caused by short-term loads such as stiletto heels. Even these tests are typically performed on the product in an uninstalled condition.

5) Static load testing differs from dynamic load testing. Static load testing gently places a load on the floor for a specified time, gently removes the load at the end of the test, then after another given time the location where the load was placed is measured for residual indentation. Dynamic loads are created when a load is placed on the floor, and then moved around the floor's surface by a rolling, sliding or dragging motion.

Below are some examples of static and dynamic loads:

- Desks, tables and filing cabinets are common examples of static loads. A desk weighing 400 lbs, with four feet, each having approximately one square inch of contact with the floor would generate a load of l00 PSI at each foot on the floor's surface.

- An occupied hospital bed weighing approximately 700 pounds, with four wheels each having 0.3 square inches of contact area would produce a floor loading of 583 PSI per wheel. Moving or sliding the bed while the wheel brake is engaged introduces a dynamic component and therefore would not be considered a normal static load situation. In recent years, flooring damage caused by hospital beds has become more common. A bed 1ike the one described in this example, in a genuine static load situation, may produce at most a slight but noticeable indentation in the installed flooring. It is the introduction of the dynamic component (sliding/moving) in combination with the high loads exerted by the wheels that can produce far more damaging results. Rips, tears, gouges, displacement of adhesive and delamination of the flooring can result from this combination of forces. A static load rating on an uninstalled flooring sample does not reflect the product's ability to withstand the unique forces generated in these types of dynamic situations without damage to the integrity of the flooring. In this case of dynamic loading, most resilient flooring manufacturers recommend that resilient flooring should be installed directly on the concrete using a reactive hard set adhesive where heavy moving loads are anticipated. Hospital bed manufacturers should provide equipment with anticipated PSI loading, preferably below 250 PSI, and on the extreme side, below 750 PSI in addition to notifying end users that special precautions should be taken in the selection of the flooring system and installation technique-

- Stiletto heels, although representing a potentially high PSI loading, are not considered a static load condition. The amount of time the load is in contact with the surface of the floor is generally short and more dynamic in nature.

Based on the examples above, three objectives become apparent:

- It needs to be clearly communicated that the current static load limit values reflect the capabilities of the product from a quality control standpoint and may not reflect the installed performance.

- The static load test method needs to be revised or a new test method developed to better reflect the static load limit performance of an installed floor.

- A new or modified test method needs to be developed to provide information on product durability under heavy dynamic loads.

Static load limit is one characteristic of a floor's durability; others include i.e., stain resistance, puncture resistance, and ease of maintenance. No flooring product is indestructible.

Misleading product claims that do not reflect a floor's performance relative to the intended use does the entire flooring industry a disservice by potentially leaving a customer dissatisfied because

of unfulfilled or mismatched expectations.

There is work under development within ASTM to address the issue of potential damage that can be caused by shifting heavy loads on the surface of a floor. Ideally ASTM will be successful in

developing a static load test method utilizing an installed assembly and/or the development of a dynamic load test to evaluate the ability of the floor to withstand movement under a load. Until new

testing methodology is developed, the best advice is to judge the technical information and merit of a flooring product upon what is ultimately covered or not covered by a floor product warranty.

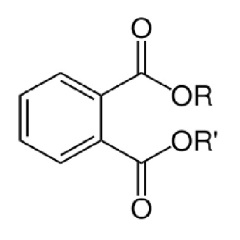

2. PLASTICIZERS / PHTHALATES

Phthalates (pronounced /ˈθæˌleɪts/, tha-layts [1]), or phthalate esters, are esters of phthalic acid and are mainly used as plasticizers (substances added to plastics to increase their flexibility, transparency, durability, and longevity). They are used primarily to soften polyvinyl chloride (PVC). Phthalates are being phased out of many products in the United States, Canada, and European Union over health concerns.

Phthalates are used in a large variety of products, from enteric coatings of pharmaceutical pills and nutritional supplements to viscosity control agents, gelling agents, film formers, stabilizers, dispersants, lubricants, binders, emulsifying agents, and suspending agents. End-applications include adhesives and glues, electronics, agricultural adjuvants, building materials, personal-care products, medical devices, detergents and surfactants, packaging, children's toys, modeling clay, waxes, paints, printing inks and coatings, pharmaceuticals, food products, and textiles.

Phthalates are easily released into the environment because there is no covalent bond between the phthalates and plastics in which they are mixed. As plastics age and break down, the release of phthalates accelerates. People are commonly exposed to phthalates, and most Americans tested by the Centers for Disease Control and Prevention have metabolites of multiple phthalates in their urine. Because phthalate plasticizers are not chemically bound to PVC, they can easily leach and evaporate into food or the atmosphere. Phthalate exposure can be through direct use or by indirect means through leaching and general environmental contamination. Diet is believed to be the main source of di-2-ethyl hexyl phthalate (DEHP) and other phthalates in the general population. Fatty foods such as milk, butter, and meats are a major source.

In studies of rodents exposed to certain phthalates, high doses have been shown to change hormone levels and cause birth defects.

Phthalates are used in a large variety of products, from enteric coatings of pharmaceutical pills and nutritional supplements to viscosity control agents, gelling agents, film formers, stabilizers, dispersants, lubricants, binders, emulsifying agents, and suspending agents. End-applications include adhesives and glues, agricultural adjuvants, building materials, personal-care products, medical devices, detergents and surfactants, packaging, children's toys, modelling clay, waxes, paints, printing inks and coatings, pharmaceuticals, food products, and textiles. Phthalates are also frequently used in soft plastic fishing lures, caulk, paint pigments, and sex toys made of so-called "jelly rubber". Phthalates are used in a variety of household applications such as shower curtains, vinyl upholstery, adhesives, floor tiles, food containers and wrappers, and cleaning materials. Personal-care items containing phthalates include perfume, eye shadow, moisturizer, nail polish, liquid soap, and hair spray. They are also found in modern electronics and medical applications such as catheters and blood transfusion devices. The most widely used phthalates are the di-2-ethyl hexyl phthalate (DEHP), the diisodecyl phthalate (DIDP), and the diisononyl phthalate (DINP). DEHP is the dominant plasticizer used in PVC due to its low cost. Benzylbutylphthalate (BBP) is used in the manufacture of foamed PVC, which is mostly used as a flooring material. Phthalates with small R and R' groups are used as solvents in perfumes and pesticides.

Globally, approximately six million tones of plasticisers are consumed every year, of which European consumption accounts for approximately 1 million tones. They contribute 10-60% of plastic products by weight. More recently in Europe, regulatory developments have resulted in a change in phthalate consumption, with the higher phthalates (DINP and DIDP) replacing DEHP as the plasticiser of choice owing to the fact that DIDP and DIP are not classified as hazardous. DEHP, although most applications are shown to pose no risk when studied using recognsied methods of risk assessment, has been classified as a Category 1A reprotoxin and is now on the Annex XIV of the EU REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) legislation which means that producers and users will need to submit authorisation requests to the European Chemicals Agency in Helsinki to continue to use DEHP. Analysis of such applications will involve studies on alternatives and, given the wide number of compounds that have been used as plasticisers, such eveluations are likely to be far reaching.

The development of cellulose nitrate in 1846 led to the patent of castor oil in 1856 for use as the first plasticizer. In 1870, camphor became the more favored plasticizer for cellulose nitrate. Phthalates were first introduced in the 1920s and quickly replaced the volatile and odorous camphor. In 1931, the commercial availability of polyvinyl chloride and the development of di-2-ethylhexyl phthalate began the boom of the plasticizer PVC industry.

Phthalate esters are the dialkyl or alkyl aryl esters of phthalic acid (also called 1,2-benzenedicarboxylic acid, not be confused with the structurally isomeric terephthalic or isophthalic acids ); the name phthalate derives from phthalic acid, which itself is derived from word "naphthalene". When added to plastics, phthalates allow the long polyvinyl molecules to slide against one another. The phthalates have a clear syrupy liquid consistency and show low water solubility, high oil solubility, and low volatility. The polar carboxyl group contributes little to the physical properties of the phthalates, except when R and R' are very small (such as ethyl or methyl groups). They are colorless, odorless liquids produced by reacting phthalic anhydride with an appropriate alcohol (usually 6- to 13-carbon).

The mechanism by which phthalates and other molecules afford plasticisation to polar polymers has been a subject of intense study since the 1960s. The mechanism is one of a polar interactions between the polar centres of the phthalate molecule (the C=O functionality) and the positively charged areas of the vinyl chain, typically residing on the carbon atom of the carbon-chlorine bond. In order for this to be established, the polymer needs to be heated in the presence of the plasticiser, first above the Tg of the polymer and then into a melt state. This enables an intimate mix of polymer and plasticiser to be formed, and for these interactions to occur. When cooled, these interactions remain and the network of PVC chains cannot reform (as is present in unplasticised PVC, or PVC-U). The alkyl chains of the phthalate then screen the PVC chains from each other as well. This explains why small changes in the length of these chains produce small changes in the level of plasticisation.

In a 2008 Bulgarian study, higher dust concentrations of DEHP were found in homes of children with asthma and allergies, compared with healthy children's homes. The author of the study stated, "The concentration of DEHP was found to be significantly associated with wheezing in the last 12 months as reported by the parents." Phthalates were found in almost every sampled home in Bulgaria. The same study found that DEHP, BBzP, and DnOP were in significantly higher concentrations in dust samples collected in homes where polishing agents were used. Data on flooring materials was collected, but there was not a significant difference in concentrations between homes where no polish was used that have balatum (PVC or linoleum) flooring and homes with wood. High frequency of dusting did decrease the concentration.

In general, children's exposure to phthalates is greater than that of adults. In a 1990s Canadian study that modeled ambient exposures, it was estimated that daily exposure to DEHP was 9 μg / kg bodyweight / day in infants, 19 μg / kg bodyweight / day in toddlers, 14 μg / kg bodyweight / day in children, and 6 μg / kg bodyweight/day in adults. Infants and toddlers are at the greatest risk of exposure, because of their mouthing behavior. Body-care products containing phthalates are a source of exposure for infants. The authors of a 2008 study "observed that reported use of infant lotion, infant powder, and infant shampoo were associated with increased infant urine concentrations of [phthalate metabolites], and this association is strongest in younger infants. These findings suggest that dermal exposures may contribute significantly to phthalate body burden in this population." Though they did not examine health outcomes, they noted that "Young infants are more vulnerable to the potential adverse effects of phthalates given their increased dosage per unit body surface area, metabolic capabilities, and developing endocrine and reproductive systems."

Infants and hospitalized children are particularly susceptible to phthalate exposure. Medical devices and tubing may contain 20-40% Di-2-ethylhexyl phthalate (DEHP) by weight, which “easily leach out of tubing when heated (as with warm saline/blood)”. Several medical devices contain phthalates including, but not limited to, IV tubing, gloves, nasogastric tubes and respiratory tubing. The Food and Drug Administration did an extensive risk assessment of phthalates in the medical setting and found that neonates may be exposed to five times greater than the allowed daily tolerable intake. This finding led to the conclusion by the FDA that, “Children undergoing certain medical procedures may represent a population at increased risk for the effects of DEHP.”

In 2008, the Danish Environmental Protection Agency (EPA) found a variety of phthalates in erasers and warned of health risks when children regularly suck and chew on them. The European Commission Scientific Committee on Health and Environmental Risks (SCHER), however, considers that, even in the case when children bite off pieces from erasers and swallow them, it is unlikely that this exposure leads to health consequences.

Phthalates are also found in medications, where they are used as inactive ingredients in producing enteric coatings. It is not known how many medications are made using phthalates, but some include omeprazole, didanosine, mesalamine, and theophylline. A recent study found that urinary concentrations of monobutyl phthalate, the DBP metabolite, of mesalamine users was 50 times higher than the mean of nonusers (some formulations of mesalamine do not contain phthalates). The study showed that exposures from phthalate-containing medications can far exceed population levels from other sources. DBP in medications raises concern about health risks due to the high level of exposures associated with taking these medications, especially in vulnerable segments of the population, including pregnant women and children.[9]

In 2008, the United States National Research Council recommended that the cumulative effects of phthalates and other antiandrogens be investigated. It criticized US EPA guidances, which stipulate that, when examining cumulative effects, the chemicals examined should have similar mechanisms of action or similar structures, as too restrictive. It recommended instead that the effects of chemicals that cause similar adverse outcomes should be examined cumulatively. Thus, the effect of phthalates should be examined together with other antiandrogens, which otherwise may have been excluded because their mechanisms or structure are different.

Studies of girls have found correlations between precocious puberty and exposure to phthalates, although a single study reported no link and concluded differently.

Much of the current research on effects of phthalate exposure has been focused towards children and men’s health, however, women may be at higher risk for potential adverse health effects of phthalates due to increased cosmetic use. Diethyl phthalate and dibutyl phthalate are especially ubiquitous in cosmetics and personal care products. According to in vivo and observational studies by Davis et al. (1994) and Lopez-Carillo et al. (2010), there is an association between phthalate exposure and endocrine disruption leading to development of breast cancer. Furthermore, it has been well documented that endocrine disruptors such as phthalates can be additive, so even very small amounts can interact with other chemicals to have cumulative, adverse “cocktail effects” Though the number of studies on phthalate and breast cancer is limited, this should not be reason enough to allow their use in personal care products.

Phthalate parent compounds and/or their metabolites have recently been implicated as a cause of breast cancer (BC). A 2010 study published in Environmental Health Perspectives for the first time implicated that the exposure to diethyl phthalates (DEP), a parent compound of the monoethyl phthalate (MEP) metabolite, may be associated with increased risk of BC (Odds Ratio of 2.20, p value for trend, p<0.003). The case-control study was age matched to 233 BC cases residing in northern Mexico. The phthalate level was determined in urine samples collected pretreatment from the cases. This is only a preliminary finding therefore additional research is required. Interestingly, exposure to the parent phthalate, butylbenzyl phthalate (BBzP) of the monobenzyl phthalate (MBzP) metabolite showed a negative association with breast cancer (Odds ratio=0.46, p value for trend, p<.008). This finding may be associated with the demethylation of the estrogen receptor complex in breast cancer cells of this particular phthalate resulting in a negative effect. This explanation will require further confirmatory research since confounders may be playing an unknown role. It is also known that DEP is found in a high proportion of personal care products, deodorants and perfumes whereas in contrast, BBzP is not detected in most deodorants and hair products and in less than one-third of all products tested , so degree of exposure may also be influencing results. A higher phthalate tertile (microgram/g creatinine) of DEP/MEP was compared to a lower phthalate tertile of BBzP/MBzP in this study.

In most cases of breast cancer the cause is unknown and less than 25% of patients have a history of commonly associated risk factors. such as: early menarche, later age at first childbirth, nulliparity, family history of BC, or history of benign breast biopsy Environmental and genetic factors may play a role in breast cancer and should be evaluated by conducting further research.

In studies of rodents exposed to certain phthalates, high doses have been shown to change hormone levels and cause birth defects. A recent British study showed that the phthalate di(n-butyl) phthalate (DBP) or its metabolite monobutyl phthalate (MBP) suppresses steroidogenesis by fetal-type Leydig cells in primates as in rodents.[16]

In a study published in 2005, lead investigator Dr. Shanna Swan reported in the "Swan Study" that human phthalate exposure during pregnancy results in decreased anogenital distance among baby boys. In this study, phthalate metabolites were measured in urine samples collected from the pregnant women who gave birth to the infants. After birth, the genital features and anogenital distance of these women's babies were measured and correlated with the residue levels in the mother's urine. Boys born to mothers with the highest levels of phthalates were 7 times more likely to have a shortened anogenital distance. An editorial concerning this paper in the same volume stated that the study population was small, and "needs to be investigated more thoroughly in a larger, more diverse population". While anogenital distance is routinely used as a measure of fetal exposure to endocrine disruptors in animals,[19] this parameter is rarely assessed in humans, and its significance is unknown. One paper states that "Whether anogenital distance measurements in humans relate to clinically important outcomes remains to be determined," and a National Toxicology Program expert panel concluded that anogenital distance is a "'novel index' whose relevance in humans 'has not been established,'" and that there is "insufficient evidence in humans" that DEHP causes harm. The Swan study is thought by some to "suggest that male reproductive development in humans could be affected by prenatal exposure to environmentally relevant levels of phthalates". Authors of a more recent study of boys with undescended testis hypothesized that exposure to a combination of phthalates and anti-androgenic pesticides may have contributed to that condition.

In contrast to the Swan study, an earlier study found that "adolescents exposed to significant quantities of DEHP as neonates showed no significant adverse effects on their physical growth and pubertal maturity." This study, however, examined children exposed intravenously to phthalate diesters, and intravenous exposure results in little metabolic conversion of the relatively nontoxic phthalate diester to its more toxic monoester metabolite.

In November 2009, Swan et al., in the International Journal of Andrology, in a paper titled "Prenatal phthalate exposure and reduced masculine play in boys",

"... suggest that prenatal exposure to antiandrogenic phthalates may be associated with less male-typical play behaviour in boys. ... [and] ... suggest that these ubiquitous environmental chemicals have the potential to alter androgen-responsive brain development in humans."

There may be link between the obesity epidemic and endocrine disruption and metabolic interference. Studies conducted on mice exposed to phthalates in utero did not result in metabolic disorder in adults. However, "in a national cross-section of U.S. men, concentrations of several prevalent phthalate metabolites showed statistically significant correlations with abnormal obesity and insulin resistance." Mono-ethyl-hexyl-phthalate, a metabolite of DEHP, has been found to interact with all three peroxisome proliferator-activated receptors (PPARs). PPARs are members of the nuclear receptor superfamily. The author of the study stated "The roles of PPARs in lipid and carbohydrate metabolism raise the question of their activation by a sub-class of pollutants, tentatively named metabolic disrupters." Phthalates belong to this class of metabolic disruptors. It is a possibility that, over many years of exposure to these metabolic disruptors, they are able to deregulate complex metabolic pathways in a subtle manner.

Large amounts of specific phthalates fed to rodents have been shown to damage their liver and testes, and initial rodent studies also indicated hepatocarcinogenicity. Following this result, diethyl hexyl phthalate was listed as a possible carcinogen by IARC, EC, and WHO. Later studies on primates showed that the mechanism is specific to rodents - humans are resistant to the effect. The carcinogen classification was subsequently withdrawn.

In 2004, a joint Swedish-Danish epidemiologic team found a link between allergies in children and the phthalates DEHP and BBzP. Their review article and meta-analysis of published data relating to phthalates and asthma found an association between phthalates in the home and asthma, especially in children, but this evidence was limited by imprecise data on levels of exposure.[31]

In 2007, a cross-sectional study of U.S. males concluded that urine concentrations of four phthalate metabolites correlate with waist size and three phthalate metabolites correlate with the cellular resistance to insulin, a precursor to Type II diabetes. The authors note the need for follow-up longitudinal studies, as waist size is known to correlate with insulin resistance.

A 2009 study published in the Journal of Pediatrics found that prenatal phthalate exposure was related to low birth weight in infants. Low birth weight is the leading cause of death in children under 5 years of age and increases the risk of cardiovascular and metabolic disease in adulthood. Researchers at the University of Michigan School of Public Health found that women who deliver prematurely have, on average, up to three times the phthalate level in their urine compared to women who carry to term.

In 2009, South Korean scientists reported findings of a statistically-significant correlation between urine phthalate concentrations in children and symptoms of ADHD. Although more research is needed in order to conclusively determine the relationship between phthalate and ADHD, the article suggests that consumers should be aware of its potential effects on behavior and neurological disorders. The findings were replicated in The Mount Sinai Children's Environmental Health Study, which enrolled a multiethnic prenatal population in New York City between 1998 and 2002 (n= 404), published in Jan 2010. There was an association of prenatal phthalate exposure with offspring behavior and executive functioning at ages 4 to 9 years. there are associations between phthalate metabolite urinary concentrations and body size measures in New York City children http://www.sciencedirect.com/science/article/pii/S0013935111003112

Biological alternatives

There are numerous biological alternatives on the market. The problem is that they are typically expensive and not compatible as a primary plasticizer.

A plasticizer based on vegetable oil has been developed which uses single reactor synthesis and is compatible as a primary plasticizer. It is a ready substitute for dioctyl pthalate.

United States

In August 2008, the United States Congress passed and President George W. Bush signed the Consumer Product Safety Improvement Act (CPSIA), which became public law 110-314. Section 108 of that law specified that as of February 10, 2009, "it shall be unlawful for any person to manufacture for sale, offer for sale, distribute in commerce, or import into the United States any children’s toy or child care article that contains concentrations of more than 0.1 percent of" DEHP, DBP, or BBP and "it shall be unlawful for any person to manufacture for sale, offer for sale, distribute in commerce, or import into the United States any children’s toy that can be placed in a child’s mouth or child care article that contains concentrations of more than 0.1 percent of" DINP, DIDP, DnOP. Furthermore, the law requires the establishment of a permanent review board to determine the safety of other phthalates. Prior to this legislation, the Consumer Product Safety Commission had determined that voluntary withdrawals of DEHP and DINP from teethers, pacifiers, and rattles had eliminated the risk to children, and advised against enacting a phthalate ban.

Some phthalates were restricted in children's toys sold in California starting in 2009.

Phthalates are used in some but not all PVC formulations, and there are no specific labeling requirements for phthalates. PVC plastics are typically used for various containers and hard packaging, medical tubing, and bags, and are labelled "Type 3" for recycling reasons. However, the presence of phthalates rather than other plasticizers is not marked on PVC items. Only unplasticized PVC (uPVC), which is mainly used as a hard construction material, has no plasticizers. If a more accurate test is needed, chemical analysis, for example by gas chromatography or liquid chromatography, can establish the presence of phthalates.

Polyethylene terephthalate ethylene (PETE) is the main substance used to package bottled water and many sodas. Products containing PETE are labeled "Type 1" (with a "1" in the recycle triangle) for recycling purposes. Although the word "phthalate" appears in the name, PETE does not use phthalates as plasticizers. The terephthalate polymer PETE and the phthalate ester plasticizers are chemically different substances. Despite this, however, a number of studies have found phthalates such as DEHP in bottled water and soda. One hypothesis is that these may have been introduced during plastics recycling. Several studies tested the liquids before they were bottled, in order to make sure the phthalates came from the bottles rather than already being in the water.

GREEN OR UNION YELLOW

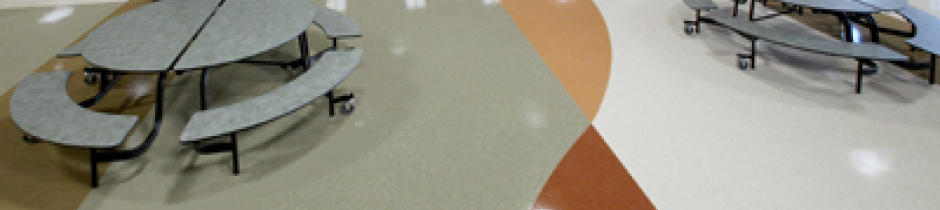

RESILIENT FLOOR COVERING COME IN MANY DIFFERENT WAYS.

In the last decade, building products with claims by their manufacturers of being "green" or "sustainable" have become increasingly common. Some of these claims have been readily discernable and verifiable while others have been more difficult to evaluate. In certain cases, controversy has arisen between those making the claims, such as manufacturers, and those trying to make objective, informed, design decisions such as architects and interior designers. In the case of resilient flooring, in particular, there has been a need to gain clarity on how to determine the relative sustainability of different products, particularly since there are numerous choices in materials, manufacturing processes, suppliers and applications. Manufacturers of many building products have needed to be careful that claims on their green characteristics have not been misleading in order to remain legally and ethically appropriate. In response to the need for an objective way for designers, specifiers and purchasers of resilient flooring products to make better decisions when selecting floor coverings for green and sustainable buildings, a new national standard has been developed.

NSF/ANSI Standard 332-2010

Sustainability Assessment

NSF International (formerly the National Sanitation Foundation) is an independent, not-for-profit standards developer that has developed a new sustainability assessment standard for resilient floor coverings that has also been approved by the American National Standards Institute (ANSI) as meeting the ANSI standard-setting requirements. The new NSF American National Standard 332-2010: "Sustainability Assessment Standard for Resilient Floor Coverings" (NSF 332) can now be used by architects, designers, owners, facility managers and end users to determine for themselves the reliability of the sustainability attributes of a range of resilient flooring products. While the standard is offered as a self-assessment for manufacturers, its credibility is derived from having been developed through the open, consensus-based ANSI process with public review and input. Further, optional third-party certification under this standard offers specifiers the highest level of confidence and credibility in a market that has no shortage of green claims. The goal is to make it easier to evaluate the sustainability profile of resilient floor coverings, and to enable the resilient floor covering industry to offer flooring products with increased sustainability.

In the broadest sense, resilient flooring is usually defined as a hard surface flooring material but with some "give" or "resilience" when walked on that bounces right back to its original configuration. Within Standard 332, resilient flooring is specifically defined as "a floor surfacing material made in sheet or tile form, or formed in place as a seamless material that has a wearing surface that is not textile." A key distinction is that the wearing surface is non-textile such as would be found in carpets and covered under other standards. Examples of resilient floor coverings include vinyl tile, vinyl composition tile, sheet vinyl, luxury vinyl tiles and planks, cork, rubber, polymeric, and linoleum flooring products. Also included are accessories such as wall base, moldings and stair treads.

NSF 332 is based on providing "a thorough communication of information that is verifiable, accurate and not misleading about environmental and social aspects associated with the production and use of resilient floor coverings." The standard is "intended to be science based, provide transparency, and offer credibility for manufacturers in making claims of environmental preferability and sustainability, and to harmonize the principles and procedures used to support such claims." While the standard is intended to be used primarily by product manufacturers, it is expected that it will also be used by independent auditors, certification bodies and environmental labeling organizations, architects, designers, and purchasers in determining market-based environmental and sustainability claims. Overall, the standard offers a consistent approach to the evaluation and determination of environmentally preferable and sustainable resilient floor coverings and includes relevant criteria across the product's full life cycle from product design, through manufacturing, use and end-of-life management. In addition to all of the above, the standard is deemed applicable to products manufactured in one facility or multiple facilities, one country or multiple countries.

Under NSF leadership NSF 332 was developed using the ANSI consensus-based process that included architects, academia, environmental program managers, the U.S. Environmental Protection Agency (EPA), state and federal agencies responsible for procurement practices, and flooring manufacturers. The standard is built upon scientific principles including the International Standards Organization (ISO) 14000 series Environmental Standards. It took over three years to complete the process that included a two-year public comment and voting period. NSF 332 was first released as a draft standard and ultimately received final ANSI approval in 2010. The development committee included representatives from the Resilient Floor Covering Institute (RFCI). RFCI is a nonprofit industry trade association representing the major manufacturers of resilient flooring, raw material suppliers and sundry product producers (e.g. adhesives). RFCI currently works with Scientific Certification Systems (SCS) to administer FloorScore®, which certifies hard-surface flooring complying with the indoor air quality program for VOC emissions under California Section 01350 (CDPH/EHLB Stnadard method VI.1-February 2010) and LEED IEQ 4.1 and 4.3. Hundreds of hard-surface flooring materials and adhesives currently bear the FloorScore® seal.

Understanding NSF/ANSI Standard 332

From the outset, the intent was to develop a comprehensive standard that looked at multiple criteria so that products could be assessed based on multiple attributes of that product, not just a single attribute. Single-attribute standards serve a purpose but multi-attribute standards are regarded as more indicative of determining such things as an Environmentally Preferable Product (EPP) as mandated by many government agencies. NSF 332, which uses the multi-attribute approach, is responsive to market requests for a more comprehensive tool just as FloorScore® responded to market demands for measuring VOC emissions which impact indoor air quality.

Criteria Category Groupings

Six categories of potential environmental impact to be evaluated are included in NSF 332. The criteria are grouped in general conformance with a product's life cycle, from design (including raw material selection and their production) to manufacturing, use and end of life. Additionally, criteria related to corporate governance are included to address issues of social responsibility. The six categories are as follows:

Product design that encourages manufacturers to integrate environmental and life-cycle thinking into the product's design process. Product manufacturing processes that encourages manufacturers to quantify the environmental impacts from their manufacturing, and then act to reduce or remove those impacts Long-term value encouraging manufacturers to maximize product longevity End-of-life management encouraging existing and new resilient flooring products to be collected, processed, recycled, and/or composted within the existing material's recycling infrastructure. Corporate governance encouraging corporate social responsibility in the form of providing a desirable workplace, being involved in the local community, and demonstrating financial health. Innovation (optional) to give manufacturers the opportunity to be awarded points for exceptional performance above the requirements set forth in NSF 332. Scoring Methodology For resilient flooring manufacturers that choose to assess the sustainability performance of their products in accordance with this standard, a point-based scoring system has been developed. The system is based on a 90-point scale with a varying number of points assigned to accomplishing each of the assessment categories. Note that the Innovation category is optional and allows for 10 bonus points beyond the 90 available in the other categories for a total maximum potential score of up to 100 points. The category point breakdown is as follows:

1.) Product Design – up to 30 points

2.) Product Manufacturing – up to 29 points

3.) Long-Term Value – up to 9 points

4.) End-of-Life Management – up to 10 points

5.) Corporate Governance – up to 12 points

6.) Innovation – up to 10 points

Labeling, Reporting and Certification

The methodology for assessing whether a product conforms to the environmental and social responsibility criteria and for verifying ongoing conformance begins with the manufacturer. Each manufacturer self-certifying under NSF 332 is responsible for creating appropriate documentation in sufficient detail to ensure confidence that the requirements in the standard have been met. Product manufacturers making a declaration of conformance with the standard (i.e. a substantiated claim of sustainability for the product(s) assessed) should report this in a publicly available document (e.g., available on manufacturer's website). Achievement of conformance with all of the prerequisites and additional criteria allows manufacturers to declare Sustainable Product(s) Achievement declarations based on the specific point score achieved for each individual product assessed as follows:

A.) Conformant: 25 points minimum

B.) Silver: 35 points minimum

C.) Gold: 45 points minimum

D.) Platinum: 60 points minimum

When architects are preparing specifications for sustainable resilient floor coverings, the NSF/ANSI Standard 332-2010 can be identified at the Conformant level (25 points) as a minimum. For buildings and designs seeking higher levels of sustainability, Silver, Gold or Platinum levels can be specified. Note that the availability of manufacturer's products at those levels must be determined for a coordinated design. It is also important to note that these levels of sustainability can be specified independently of any other sustainability goals for the project such as LEED certification through the U.S. Green Building Council and GREEN GLOBES green building certification. This approach using defined levels of conformance was developed so that sustainability principals could be attainable by companies regardless of size or number of manufacturing plants. Note, however, that certification is for specific products made at specific plants. The same product made at a different plant which is not part of the certification process cannot bear the standard's certification.

Prerequisites Required to Conduct an Assessment

Four of the six assessment categories in NSF 332 contain a total of 11 specific prerequisites that are minimum threshold requirements under the standard. Manufacturers using the standard to demonstrate sustainability of their product must first meet all of the prerequisites in each category in order to proceed any further. Once all 11 prerequisites are met, they may then seek points toward the Sustainable Product(s) Achievement levels (Conformant, Silver, Gold or Platinum) by meeting the additional specified scoring criteria within the six categories. Note that the prerequisites as described below do not carry any points, rather they are intended to establish the minimum qualifying baseline criteria from which a product can then be judged further for sustainability under NSF 332.

The first three prerequisites are in the Product Design Category as follows:

1.) Environmental considerations in design. The manufacturer must implement an environmental assessment program within the product(s) design and development system.

2.) The program shall consider the environmental attributes and impacts of its products and packaging, including issues such as designing for longevity, designing for reusability, and designing for recyclability and/or compostability. The environmental assessment program shall consider environmental attributes and impacts of products and packaging across the entire product's life cycle (e.g., raw material extraction, manufacturing, use and end of life).

3.) Inventory of material inputs. The manufacturer must complete an inventory of material inputs for the product(s) undergoing assessment including packaging and recommended adhesive systems. At a minimum, the inventory shall report inputs by using Chemical Abstract Service (CAS) nomenclature, with inputs classified as hazardous declared to a minimum 1000 ppm (0.1 percent) threshold and other inputs to 10,000 ppm (1.0 percent) threshold. The manufacturer shall also document the environmentally sustainable nature of the materials (e.g. recycled [pre- or post-consumer], bio-based, environmentally preferable).

Identification of use of chemicals of concern.

The manufacturer must create a report classifying the raw material inputs for the product(s) undergoing assessment, including recommended adhesives, by the chemical hazard classification listed below.

At a minimum, the manufacturer must report whether the raw material input comprising at least 1000 ppm of the product(s) or adhesive is classified by any of the following: (1) the International Agency on the Research of Cancer (IARC) as a human carcinogen (Group 1) or probable human carcinogen (Group 2A); (2) the National Toxicology Program (NTP) as a known human carcinogen or reasonably anticipated carcinogen; (3) the U.S. Occupational Safety and Health Administration (OSHA) as a regulated toxic metal or carcinogen; (4) California Proposition 65 as a carcinogen or reproductive toxin; (5) U.S. EPA as a Persistent, Bioaccumlative, and Toxic (PBT) chemical; (6) U.S. EPA as a Toxic Release Inventory (TRI) toxic chemical or compound; (7) U.S. EPA as a RCRA Waste Minimization priority chemical; (8) U.S. and Canada as a Great Lakes Binational Toxics Strategy chemical; (9) the Stockholm Convention as a Persistent Organic Pollutant (POP); and (10) the European Union as a hazardous substance subject to the Restriction of Hazardous Substances (RoHS) directive.

Three prerequisites fall under the category of Product Manufacturing as follows:

1.) Environmental policy. The manufacturer must implement an environmental management policy that includes a commitment to continual improvement and pollution prevention, plus showing assurance of compliance with applicable regulations and other legal environmental requirements. This policy shall be communicated to all persons working for or on behalf of the organization, and be made publicly available.

2.) Energy inventory. The manufacturer must complete an inventory of energy use that encompasses production by quantity and source of energy. The manufacturer shall also identify type and distance of transportation of raw materials from key suppliers.

3.) Water use inventory. The manufacturer must complete an inventory of water use including identification of quantity of water used, quantity consumed (e.g., loss through evaporation), and sources (e.g., municipal potable, direct capture, on-site wells, reclaimed wastewater).

Two prerequisites fall under the category of Long-term Value as follows:

1.) Recommended usage. The manufacturer shall confirm that their resilient floor covering products are designed and manufactured to be durable and long-lasting under conditions of intended use. The manufacturer shall also demonstrate a continuous effort to communicate relevant design and product selection criteria in order to assure the product(s) are used as intended for the longest possible service life.

2.) Minimal long-term indoor volatile organic compound (VOC) emissions. The manufacturer shall demonstrate that the maximum concentration for any VOC emitted shall not result in a modeled indoor air concentration greater than half of the chronic reference exposure level (CREL) established by California Office of Environmental 3.) Health Hazard Assessment (OEHHA). A separate concentration level for formaldehyde is also established.

The final three prerequisites fall under the category of Corporate Governance and primarily address social sustainability as follows:

1.) Prevention of discrimination. The manufacturer shall demonstrate that it does not engage in or support discrimination in the employment process at the corporate level by adherence to regulations related to civil rights, equal pay, age and physical handicaps.

2.) Prohibitions on forced labor. The manufacturer shall demonstrate that it does not engage in or permit the use of forced or compulsory labor at its facilities and those of its key suppliers.

3.) Prohibitions on child labor. The manufacturer shall demonstrate that it does not operate facilities or source key supplies that do not follow international standards on child labor.

With the prerequisites satisfied, a user of the standard is then ready to delve into the specific scoring criteria of each of the six categories as summarized on the following pages. A copy of the summary scoring sheet included in the standard is shown in the table below.

Product Design Category Scoring Criteria

The stated purpose of the Product Design category is to "encourage manufacturers to integrate environmental and life-cycle thinking into the product design process" and is worth up to 30 points on the 90 point scale. Along with three prerequisites already described, the assessment for this category is broken down into four subcategories each containing specific criteria within as follows:

Enlightened Design Process

The criteria in this subcategory are intended to encourage the understanding of environmental impacts of products by the product designers and developers including the following:

Life-cycle assessment (LCA) or Design for Environment (DfE) assessment. By demonstrating that a full life cycle assessment has been completed using any of a number of nationally recognized standards or programs for that purpose within the past three years relative to the product(s) undergoing assessment, the manufacturer can receive up to 3 points. At a minimum, the life-cycle impact categories characterized must include global warming, acidification, ozone depletion, photochemical smog formation and eutrophication.

Life-cycle assessment improvement.

The manufacturer can also receive one point for demonstrating an impact reduction of at least 10% from an established baseline in a minimum of two impact categories as listed above. The baseline shall be no longer than five years prior to the current product certification year.

Environmentally sustainable material inputs.

For the product(s) undergoing assessment, credit is given for demonstrating that the manufacturer is fully informed as to the material composition of its products, including packaging and recommended adhesive systems. The criteria are also meant to encourage the selection and use of component materials manufactured wholly or in part from environmentally sustainable inputs such as recycled materials (post-consumer and post-industrial) and bio-based resources.

Environmentally sustainable inputs for product(s).

For the product(s) undergoing assessment, the manufacturer can earn up to 8 points by declaring the total quantity of environmentally sustainable inputs specified on a percentage weight basis for recycled (pre- or post-consumer) content or bio-based content.

Environmentally sustainable inputs for packaging.

An additional 2 points are available by also declaring the total quantity of environmentally sustainable inputs of the packaging materials specified on a percentage weight basis for recycled or bio-based packaging materials.

Human and ecologically friendly inputs

These subcategory criteria are intended to ensure that the manufacturer is fully informed as to the human and ecological hazards associated with the chemical composition of its products, including the recommended adhesive systems. These criteria are also meant to encourage the use of environmentally compatible chemicals while minimizing and eliminating the use of chemicals of concern, which have been identified in the lists specified in the prerequisite for the "Identification of use of chemicals of concern." Using those lists, there are three actions that can receive points:

A.) Minimization of known chemicals of concern in product. The manufacturer can receive up to 5 points for demonstrating raw material input information that the product(s) does not contain: (1) any known carcinogen or reproductive toxin at levels equal to or greater than 1000 ppm (0.1%) or the level that requires labeling under California Proposition 65, whichever is higher; and (2) any OSHA toxic metal, TRI PBT, or TRI toxic chemical or compound at levels equal to or greater than 1000 ppm.

B.) Minimization of known chemicals of concern in recommended adhesive. The manufacturer can receive one point for demonstrating that no chemical listed as a carcinogen or reproductive toxin comprises more than 0.1% (1000 ppm) of the total mass of the adhesive.

C.) Elimination of chemicals with upstream concerns. For those material inputs present in the product(s) at levels equal to or greater than 5%, the manufacturer can receive up to two points for demonstrating that one step upstream of the life cycle manufacturing boundaries does not release known PBT or listed TRI toxic chemicals or compounds at or above the CERCLA reportable quantity level.

Informed Selection of Suppliers

The intent of the criteria within this section is to ensure that manufacturers are aware of the environmental performance and social accountability of their supply chains.

Supplier environmental disclosure.

The manufacturer can receive one point for documenting the implementation of a key supplier environmental disclosure process that requires supplier disclosure of environmental performance information. This information needs to demonstrate compliance (or lack thereof) with local, regional, and national environmental requirements, presence (or absence) of a documented environmental management system, release of reportable quantities of TRI PBT's, use (or lack thereof) of renewable energy supplies, and evidence of greenhouse gas emissions tracking.

Supplier environmental performance disclosure.

For this credit, the manufacturer shall document the percent of its key suppliers that have satisfactorily conformed to the company's environmental disclosure requirements as described above. The manufacturer shall receive one point if 50 to 74 percent of its key suppliers have conformed, or receive two points if 75 percent or more of its key suppliers have conformed.

Supplier social accountability.

The manufacturer can receive one point for documenting the implementation of a supplier social accountability disclosure process. This process requires suppliers to disclose social accountability information including declaration of compliance with labor requirements and documentation of social accountability conformance.

Supplier social accountability disclosure.

The manufacturer can further choose to document the percent of its key suppliers that have satisfactorily conformed to the company's social accountability disclosure requirements as described above. The manufacturer shall receive one point if 50 to 74 percent of its key suppliers have conformed, or receive two points if 75 percent or more of its key suppliers have conformed.

Supplier audits.

The manufacturer may receive up to 2 points for first-, second- or third-party supplier audits. It shall receive 1 point if 10 percent or more of its key suppliers were audited in the past five years to verify conformance with environmental or social accountability disclosure requirements. It shall receive a second point if it has conducted annual reviews of 10 percent or more of its key suppliers.

Product Manufacturing Category Scoring Criteria

The criteria under this second category are focused on manufacturing and are intended to "encourage manufacturers to quantify the environmental impacts from their manufacturing, and then act to reduce or remove those impacts." Organized into five sub-categories, it includes the three prerequisites related to environmental policy, energy inventory, and water use inventory plus the ability to earn up to 29 points based on the criteria below:

Environmental Policy and Management

The intent of these criteria is to ensure that manufacturers have a basis from which to include strategic environmental management within their organization.

Registered EMS system.

The manufacturer can receive three points for documenting that its Environmental Management System (EMS) system is certified under ISO 14001 by a third party certifier.

Maintaining environmental attributes through manufacturing.

The manufacturer can receive one point for implementing a tracking system to ensure that design criteria specified in its EMS system are not cost-engineered or otherwise modified during the manufacturing process.

Conservation of Energy Resources

A manufacturer can reduce its environmental impact by means of its energy initiatives: both reduction of consumption (i.e., conservation) and selection of source (i.e., renewable sources). The criteria below encourages both approaches in order to reduce the environmental impacts from energy production and consumption, including resource depletion, greenhouse gas emissions and hazardous air pollutants.

Reduction of environmental impact of energy input.

The manufacturer can demonstrate overall reduction in the environmental impact of its energy inputs on a unit product(s) basis, facility basis or total manufacturing operation of compliant or similar product(s). Reduction must be calculated from the year 2000 or later. Impact reduction shall be quantified based on measured reductions in energy consumption (i.e. direct fuel, electricity, steam) and/or conversion of energy inputs from non-renewable resources (e.g., fossil fuels) to renewable alternatives. Significantly, the manufacturer can receive between 2 to 10 points based on a chart within the Standard corresponding to reductions from 1 percent to over 35 percent.

Management of Water Resources

The criteria within this category encourage the conservation of water sources and protection of water quality.

Reduced water consumption. The manufacturer can receive one point on a per-unit basis from the year 2000 or later for an average of 1 percent water reduction per year over a given 5-year period or a 5 percent reduction of water consumption over the last 10 years. The manufacturer can earn up to 2 points for documenting that wastewater released either to a publicly owned treatment works (POTW), or directly to the environment, is of a quality equal to or better than the quality of the supplied water according to established standards.

Optimization of Material Resources

The criteria here are intended to encourage the maximization of yield from product(s) raw materials and to minimize the generation of waste materials during production. The manufacturer can receive one point for having a documented and operational waste minimization program that includes quantification of waste generation rate.

Manufacturing waste minimization.

The manufacturer can receive either one point for demonstrating a waste generation reduction rate of at least 10 percent over the previous 10 years or two points for demonstrating an annual average total waste generation rate of less than 2 percent on a weight basis.

Packaging minimization.

The manufacturer can incorporate packaging and delivery methods that minimize waste generation during transport and installation of product(s). It shall receive one point if a product's packaging weight is documented as constituting less than 2 percent of the product's weight. Where pallets are normally used in shipment of flooring product(s), including the pallet weight in the 2 percent requirement is waived provided a recycling or reclamation program has been documented for the used pallets.

Protection of Air Resources

These criteria are intended to minimize or eliminate the production and release of greenhouse gases and of known air contaminants.

Greenhouse gas loadings.

The manufacturer can receive two points for completing a greenhouse gas inventory for product manufacturing operations in accordance with ISO 14064 or an equivalent standard.

Greenhouse gas reduction goals. The manufacturer can receive one point for establishing greenhouse gas reduction targets equal to 5 percent reduction using 2000 as the baseline year.

Greenhouse gas reductions.

The manufacturer can demonstrate their own reduction in greenhouse gas loadings on a per unit production basis with the initial year of calculation being 2000 or later. The manufacturer can receive one point for each 10% reduction up to a maximum of three points.

PBT reductions.

The manufacturer can seek to demonstrate that emissions of PBT compounds are below US EPA reporting levels. The manufacturer can receive one point for achieving this goal in relation to emissions from its on-site activities and/or one point for achieving the goal in relation to emissions from its supplied electricity source/s, for a maximum of two total points.

Long-Term Value Category Scoring Criteria

The criteria under this category focus on encouraging manufacturers to maximize product longevity which is dependent on its durability and performance characteristics thus reducing the replacement cycle and environmental impact. Up to 9 points are available in three sub-categories after satisfying the two prerequisites of recommended usage and minimization of VOCs.

Fitness of Purpose

The criteria here are intended to demonstrate that the product(s) performs as intended in order to ensure that positive environmental attributes have not been undermined by lower-quality performance.

Durability. The manufacturer can receive 4 points for providing documentation showing that the product(s) performs at or above performance requirements as described in industry-recognized standards that are relevant to the specific product(s).

Protection of Indoor Air Quality

This criteria is meant to demonstrate that the product(s) and its associated adhesives and sealants do not release chemicals of concern or provide a pathway for other elements that are potentially

irritating and/or harmful to installers and occupants.

Total Volatile Organic Compounds (TVOC). The manufacturer can receive one point by annually tracking the TVOC emissions of the finished flooring product and showing that the TVOC level has not exceeded its defined baseline value by more than 500 ug/m3 as determined using a specified office modeling program.

De minimis indoor carcinogenic VOC emissions. The manufacturer can receive one point for demonstrating that carcinogenic or reproductive toxicant VOCs are not emitted from products at levels above the Safe Exposure Levels (SELs) as described in a specified standard.

Minimal short-term adhesive and sealant emissions.

The manufacturer can receive one point for demonstrating that adhesives and sealants (as applicable) recommended for use by the flooring manufacturer meet the VOC content limits established in specified standards.

Compatibility with green maintenance strategies.

Here the focus is on ensuring that resilient flooring products sold in the marketplace are compatible with, and encourage the use of, green maintenance strategies.

Elimination of chemicals of concern from cleaning products.

One point is available for demonstrating that the recommended cleaning products and maintenance procedures (including stripping and resealing) do not require the use of any of the listed chemicals of concern in specified lists nor contain those chemicals at levels equal to or greater than 1000 ppm (0.1 percent).

Control of VOC emissions from cleaning products.

The manufacturer can receive one point for demonstrating that recommended cleaning products do not exceed the maximum allowable VOC levels established by California for the relevant product(s) group.

End-of-Product-Life Management Category Scoring Criteria

Up to 10 points are available under this category which is intended to encourage product reclamation and recycling for resilient flooring. There are two subcategories with no prerequisites as follows:

Reclamation Feasibility

The intent here is to ensure that existing and new resilient flooring products can be collected, processed, recycled and/or composted within the existing materials recycling infrastructure.

Product(s) recyclability or compostability.

The manufacturer can receive up to 2 points for demonstrating that post-consumer collected material (including installation waste) can be: (1) recycled into a different product(s) group (e.g., vinyl tile into car bumpers); (2) composted or otherwise converted into a beneficial soil amendment (e.g., gypsum, wood dust); (3) recycled into a similar product(s) (e.g., vinyl tile into vinyl tile); or (4) recycled into a complementary product(s) group (e.g. vinyl tile into carpet tile). Recyclability claims must show that the recycled material can comprise at least 5 percent by weight of the new product(s). Composting claims must conform to ASTM D6400.

Post-consumer collection operations.

For products that have been available for sale for ten years or more, the manufacturer can demonstrate that the product(s) (including installation waste) is being collected for recycling or composting through ongoing collection operations. For new products (e.g., those with a market presence of less than 10 years), the manufacturer shall demonstrate preparation and implementation of a post-consumer collection and recovery plan. The manufacturer can receive either one point for demonstrating conforming activities within 200 miles of at least two major metropolitan areas or two points for demonstrating conforming activities for a national area.Product Reclamation and StewardshipThe intent of this sub-category is to encourage the diversion of flooring materials from landfills, and to promote the redirection of material resources into new products instead.

Post-consumer reclamation.

The manufacturer can receive one point for up to 2% post-consumer reclamation; two points for 3 percent or 4 percent post-consumer reclamation; or, at a maximum, three points for 5 percent or greater post-consumer reclamation. To qualify, the manufacturer must document, calculate, and report the product(s) post-consumer reclamation rate of products based on details set forth in the standard. Corporate investment in reclamation. The manufacturer can receive points for the percent of their revenue (annual average, maximum five-year averaging) that it commits to documented activities associated with improving the reclamation rate of its products. The manufacturer can receive one point for 0.05 percent of their revenue invested, two points for 0.10 percent of their revenue invested, or a maximum of three points for 0.15 percent or more of their revenue invested. Qualifying activities include research and development in materials processing and new product(s) development (using reclaimed materials); purchase and installation of processing equipment to be used wholly or in part for the processing of reclaimed flooring materials, including composting grinding equipment; and other quantifiable financial support of post-consumer material collection, processing, and manufacturing activities (including ongoing labor expenses).

Corporate Governance Category Scoring Criteria

The criteria in this category are focused on encouraging corporate social responsibility in terms of providing a desirable workplace, being involved in the local community, and demonstrating financial health. A total of 12 points are available in four sub-categories after satisfying the three prerequisites that prohibit discrimination, forced labor and child labor. For purposes of this category, manufacturer is interpreted as a parent corporation, a manufacturing plant, and/or a business unit.

Public Commitment to Sustainability

These criteria demonstrate corporate/organizational leadership in public disclosure and transparency of key environmental and social accountability objectives and data. The information described below can be released as part of the company's annual report, available to all who request a copy, or available online from the company's website.

Preliminary disclosure.

The manufacturer can receive one point for publicly releasing one of several forms of standardized information about their environmental management and social accountability performance, and life-cycle assessment findings.

Comprehensive disclosure (Corporate Level). The manufacturer can receive one point for demonstrating it has publicly released a corporate or plant annual sustainability report per the guidelines of the Global Reporting Initiative of the United Nations Environment Program or its annual environmental and social accountability targets and achievements.

Employer Responsibility

Employee turnover (Plant Level). One point is available for quantifying and reporting the average employee turnover rate (per year or two-year rolling average).

Employee injury rate (Plant Level).

One point is available for quantifying and declaring the average employee injury rate (per year or two-year rolling average) including occupational accidents, injuries, illnesses and disease.

Right to collective bargaining (Plant Level). One point is available for demonstrating compliance with the National Labor Relations Act requirements or the internationally recognized equivalent.

Living wages/remuneration (Plant Level).

A manufacturer can receive one point for demonstrating that non-management personnel wages are sufficient to meet basic needs of personnel and provide some discretionary income plus demonstrating that wages are paid directly to employees, with full disclosure of any required or authorized deductions (e.g., taxes, health care benefits, and retirement investments).

Company-supported employee activities

A manufacturer can receive one point for investing 10 percent or more of its net income in the community. This requires that a manufacturer declare this investment, as defined in accordance with generally accepted accounting principles, based on the average three-year rolling monetary value provided to the communities where the majority of employees reside by means of state and local taxes paid plus direct contributions (e.g., grants and investments). Employee salaries and other employee remuneration are excluded from this calculation. Taxes or investments made at the state level do not qualify unless specifically designated for allocation to the community.

Employee participation. The manufacturer can receive one point for documenting company-supported employee activities within the community. Company-supported employee activities consist of community service work performed during paid time off for that purpose, excluding activities deemed political in nature.

Local recruiting.

The manufacturer can receive one point for documenting net local employment (full-time equivalent basis) and local sourcing expenditures (U. S. dollars spent or equivalent) per year or three-year rolling average.

Financial Leadership (CorporateLevel)

The standard recognizes that "sustainability requires triple bottom line actions that are important to achieve social and environmental goals." Toward that end, the following are included:

1.) Profitability. The manufacturer can receive one point for demonstrating continued year-over-year profitability.

2.) Investment in research and development (Corporate Level). The manufacturer can receive one point for devoting 2.5 percent or more of its annual revenue to research and development activities intended to support the continuing viability of the company, including investment in emerging technologies.

3.) Vendor/supplier satisfaction (Plant or Corporate Level). The manufacturer can receive one point for reporting the percentage of contracts that were paid in accordance with agreed terms, excluding agreed penalty arrangements. Terms may include scheduling of payments, form of payment and other conditions.

Innovation Category Scoring Criteria

This optional category is intended "to give manufacturers the opportunity to be awarded points for exceptional performance above the requirements set forth in previous sections of this standard, and/or for innovative performance in categories not specifically addressed by this standard." The number of points awarded is determined on a case-by-case basis with a maximum of 10 points (in addition to the 90 point scale) available for innovation under this category. These innovation points are awarded for comprehensive strategies that demonstrate quantifiable environmental benefits and are proportional to an existing credit within the standard. The intent is to recognize novel approaches for reducing the environmental footprint of the manufacturer. In order to request an innovation credit, a manufacturer must submit a written explanation of the innovation, why it does not fit into the current categories or credits provided in the Standard and justify that the amount of points requested by drawing a parallel to the number of points awarded in a similar category. For example, a manufacturer may earn innovation points for dematerialization. In this case, credit can be provided for process and for products or product(s) lines that provide equal function using less material by percent weight per sq ft, which reduces impacts as measured over all product(s) stages.

Conclusion

Resilient flooring has a well-established presence in this country. Originally used only in high-traffic areas, vinyl flooring has become a very popular choice for flooring in just about any hard-surface application due to its superior performance characteristics when compared to other flooring alternatives. Common features such as cushioned vinyl floors and "no-wax" resilient floors are supplemented with specialty resilient floors which provide enhanced slip resistance and static conductivity developed to meet the needs of the marketplace. Resilient flooring is often used in hospitals and schools because of its easy-to-clean and moisture resistance surfaces which are crucial to controlling pathogens and limiting bacterial growth. Today, resilient flooring as a category is a strong second in floor covering sales in North America, with its market share having increased 37 percent over the past decade because of its long-lasting performance, sustainability, cleanliness, safety, value and aesthetics.

With the added demand for sustainability in buildings, the new NSF/ANSI Standard 332 can now be used to further assess these flooring products on the basis of the criteria and definitions contained within the standard. Architects and designers can then judge for themselves the degree of sustainability that they seek based on the criteria in the standard and its relationship to the green building movement in general.

3. VCT & SVT

VCT & SVT TILE

Accordingly by ASTM industry standards the words "Vinyl Tile" and "Luxury Vinyl Tile" there are only two products in the category of "Vinyl Tile": Vinyl Composition Floor Tile (VCT) and Solid Vinyl Floor Tile (SVT}. ASTM F 141, Standard Terminology Relating to Resilient Floor Coverings defines "binder content" which is the main difference between VCT and SVT. Binder consists of polymers and/or copolymers of vinyl chloride, other modifying resins and plasticizers which compress at 34 percent by weight of the finished tile. " Binder is what we call "vinyl", so SVT has to be at least 34 percent vinyl content and tile that is not is VCT,

ASTM F 1700, Standard Specification for Solid Vinyl Floor Tile classifies SVT in three categories - Class 1 Monolithic, which means through color tile with no backing; Class II Surface Decorated, which usually means an "inlaid" type tile with a backing, and Printed Film Vinyl Tile, which is a photo-graphic print with a clear vinyl wearlayer and a backing system; Class III is the most popular category, and is often called "Luxury Vinyl." These products are the wood look vinyl plank, stone, marble and granite looks that mimic the real thing so accurately. The clear wearlayer comes in many thicknesses. A minimum thickness of 0.020-inch (20 mils) will classify the product as "Commercial." Many products sold as "Luxury Vinyl" are not SVT. These products, mostly for residential use, have a backing containing a lot of filler that does not meet the 34 percent vinyl content requirement and actually are VCT.

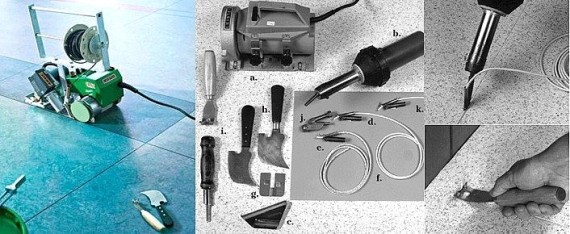

SVT INSTALLATION IS DIFFERENT FROM VCT.

Adhesive selection:

You can't use "Clear Thin Spread" and put adhesive down over large areas. Most SVT adhesives are either a wet lay or a semi-wet lay installation and in some applications it may be a reactive adhesive like epoxy or polyurethane. Reactive adhesives should be used in very high traffic areas where there is a lot of foot or rolling traffic. Examples would be elevators, lobbies, hospital patient rooms or supermarkets. Floors that get wet a lot or are exposed to cold or heat are other good examples here reactive adhesives will outperform the standard acrylic latex products.

Trowel Notch:

Often, SVT adhesive will be applied with a finer notch trowel than the standard VCT or carpet adhesive. Too much adhesive can lead to failures such as adhesive oozing, tiles shifting or indentations in the finished floor.

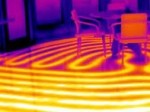

Site Conditions and Moisture Testing:

Make sure you are installing in a building that is climate controlled. The product, the adhesive, the moisture testing and the surface preparation will not be at their best if they are used in very cold or

very hot conditions. SVT is not at all "Breathable" so moisture will not pass through it. If you are installing over concrete, make sure that moisture testing has been done and the slab meets the

requirements of the adhesive and/.or the flooring manufacturer.

Acclimation:

The product itself needs to be acclimated to job site conditions for at least two days before installation. The reason for this is the tendency of vinyl products to react to temperature changes, especially warm to cold. Vinyl products such as SVT, vinyl wall base and vinyl edgings may expand slightly or they can be inadvertently stretched during handling if they are warm, such as when they come in from a hot van. Vinyl has "memory" so if it is installed in this expanded state, it will go down with joints that are nice and snug but may show gaps later in when it goes back to its original size. For this reason, acclimating vinyl products to job site conditions is just as important as it is with natural products such as wood, cork, and laminates.

Substrate Preparation:

Because SVT is very flexible, it will conform to any irregularities in the substrate. Floor prep is the